Description

Precise Leak-Free Flares!

"10x easier to use this tool than a traditional block-flare kit. Nothing gets in the way of the flare itself, and it works great in tight conditions. Durable and can take typical work punishment. I've dropped it off of a ladder 3 times, not a dent in it. Still works.” - Ashton Schmidt

Why Buy Our 1/8 To 3/4 Inch O.D. Flaring Tool?

✅POWERFUL: The 1/8 To 3/4 Inch O.D. Flaring Tool produces incredibly smooth 45-degree flares for your copper pipes that make them, even more, leak resistant and will make your customers or DIY project that much better. It doesn’t mar or constrict your copper pipes in any way and keeps them looking factory new! Works for copper, aluminum & brass tubes!

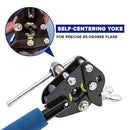

✅STRONG: This flaring tool has a self-centering yoke and automatic tube height gauge that is made of high-quality steel with durability in mind. You will find yourself flaring your copper pipes for years to come with this tool! The compact nature as well makes it incredibly easy to use in tight spaces when installing HVAC devices.

❗ Reminder ❗

- Clean and oil the face of the cone before each flare is made. Oil selection may require considerations such as refrigerant compatibility.

- Keep the tool well-lubricated. It is particularly important that the wing nut threads, the wing nut mating threads, and the feed screw threads be lubricated whenever they appear to be dry. Failure to lubricate these areas may result in undersize flares and tool damage

- The looseness of the cone feed screw assembly is intentional.

⚙️ How to use: ⚙️

1. Retract cone before wing nut is loosened. Loosen wing nut and swing clamp bolt out. Separate clamping dies as shown. Read sizes from bottom of tool. Rotate clamp dies to the desired size.

2. When tool is opened, the gauge automatically swings over tube opening. Insert tubing to gauge. CLEAN and OIL face of cone before each flare is made. Note: Oil selection may require considerations such as refrigerant compatibility.)

3. With tubing set at proper height and dies clamped together, the automatic gauge has swung out of position and tubing is ready to flare. A rather steady resistance will be felt as the cone flares the tubing. This force will suddenly increase as the tubing reaches the outer mandrel. DO NOT advance the cone further. Failure to comply can result in nicks in the flaring cone. Reverse handle and tubing will be burnished automatically.

4. After the flare has been made and the cone retracted, unclamp and remove tubing. The automatic burnishing mechanism will produce a perfect radius at neck and highly polished flare face.

📋Frequently Asked Questions:

Q: What are all of the sizes that it can fit?

A: The settings are 1/8", 1/4", 1/2" & 3/4"

Q: Can I use this to flare r22 systems?

A: Yes, it does.

GET YOURS TODAY!

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.