Description

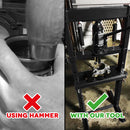

Easily Press Hard to Handle Components!

“I used this to remove and install pinion and carrier bearings on my Ford 8.8 differential and I like the compact size of the unit. It can be transferred from one point to another without any complications. it is not confined to one spot in the shop and works perfectly.” - Terry O.

Why Buy Our 6 Ton Hydraulic Shop Press?

✅CONVENIENT: This shop press is used to straighten, bend, remove and install bushings, bearings, ball joints, u-joints, pulleys, and gears for an easy repair. It also features a multi-position bed for work height adjustment and has a 6 ton capacity with a working range of up to 18”.

✅HEAVY-DUTY: It is made of durable powder-coated steel with heavy-duty springs that quickly return the ram to its position and comes with two press plates that can be used on various projects. Ideal for a small repair shop or home mechanic.

❗REMINDERS❗

- Read the entire instruction manual before use

- This press is intended for use by trained personnel. Do not use if your are not familiar with the proper operation of a hydraulic press

- Do not operate this press beyond its rated weight capacity

- Intended uses for this press include bending, pressing, and straightening

- Do not compress springs or other objects that could be ejected, or shatter

- Check the press for loose or damaged parts before each operation. Replace as needed before use

- Some parts being pressed may have a tendency to be ejected or explode when under pressure. Protect yourself accordingly. Keep hands away from the press when in use.

- Wear proper personal protective equipment (PPE) including goggles and gloves

📋Frequently Asked Questions:

Q: Would like to know if this press would be capable of pressing in and out atv/utv ball joints and bearings?

A: Yes, in most cases, this has 6 tons of force for many applications.

Q: Does it come assembled already?

A: No, but the main frame is welded together, the rest is easy to put together.

Q: How to use this?

A:

- Place the piece on the press bed

- Locate and close release valve by turning it clockwise until tight

- Pump handle until the ram is near the workpiece

- Align ram to work piece as needed

- Pump handle to apply load to the work piece. Do not overload.

- Release pressure by turning the release valve counterclockwise. Make sure your work piece is secure to prevent injury or damage

- Remove the workpiece from the press bed

Get Yours Now!

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.